Successful graduates of this course are awarded Bachelor academic degree and the professional qualification of Mechanical Engineer.

Successful graduates of this course are awarded Bachelor academic degree and the professional qualification of Mechanical Engineer.

Training is conducted in specialized laboratories equipped with modern CNC machine tools, industrial robots, 3D printer, computers and multimedia equipment.

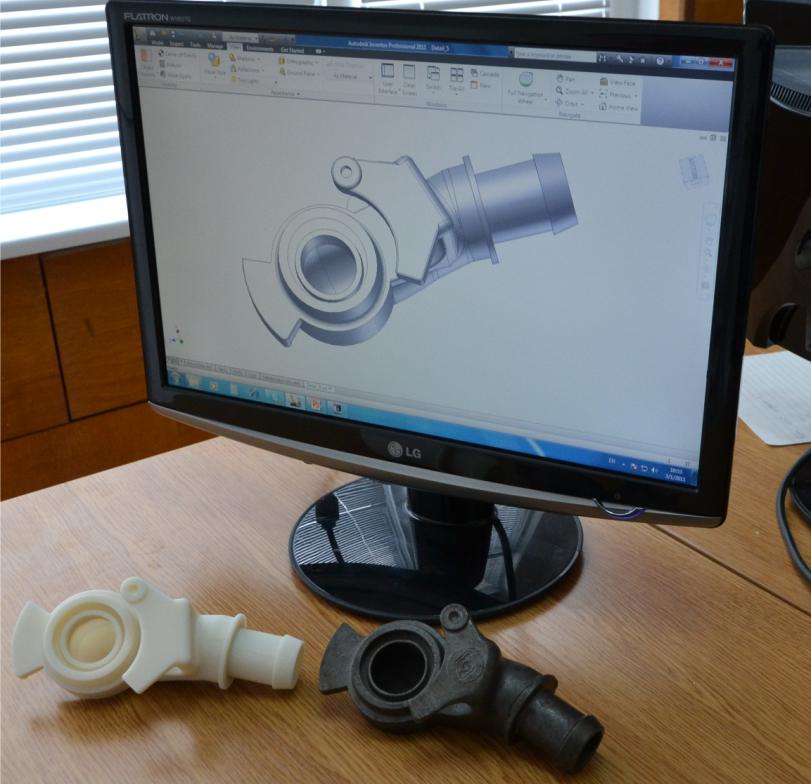

Students obtain fundamental engineering background which is set in conformity with European requirements. Computer aided design of complex products and Development of tooling equipment and respective NC programs for their manufacture are among the core subjects within this degree course.

Lower, medium and higher class CAD/CAE/CAM software is used such as AutoCAD Mechanical, INVENTOR, SolidWorks, CATIA, FeatureCAM, SinuTrain, etc . The 3D printer type uPrint facilitates students in creating true prototypes of products via Rapid Prototyping.

Lower, medium and higher class CAD/CAE/CAM software is used such as AutoCAD Mechanical, INVENTOR, SolidWorks, CATIA, FeatureCAM, SinuTrain, etc . The 3D printer type uPrint facilitates students in creating true prototypes of products via Rapid Prototyping.

The department of Mechanical Engineering Equipment and Technology is provided with 25 specialized laboratories equipped with 300 units of metal processing machinery including CNC machines, industrial robots, manufacturing and tooling equipment, computer aided measuring equipment and specialized software.

Successful course graduates will be able do design, develop and implement the production of complex units in most areas of industry by utilizing modern CAD/CAM methods and computer controlled equipment.

Successful course graduates will be able do design, develop and implement the production of complex units in most areas of industry by utilizing modern CAD/CAM methods and computer controlled equipment.